Article: Rolling Stock Technical Consultancy

The rail industry is facing a growing pressure to make trains more reliable, have them run at higher speeds and increase the network capacity, whilst improving the experience for passengers. Innovative, creative thinking is required to address these demands, whilst focusing on cost effectiveness and sustainability.

DB provides a comprehensive portfolio of rolling stock services that can help address today’s challenges. From preparing technical specifications, to design/redesign, component and vehicle testing, and predictive maintenance, we have solutions and global technical experience to tackle any rolling stock concern. With UK rolling stock engineers and an office at the heart of the rail industry, in Derby, we have played a significant role in the development of the UK’s rolling stock. This knowledge, when coupled with our global experience, makes us a strong rolling stock partner.

Whether high speed, light rail, conventional rail or metro, we have a global understanding of it all and we supply engineering consultancy in the following areas:

Brake System Technology (WSPER)

Overview

DB ESG's wheel slide protection evaluation rig (WSPER) is a real time ‘hardware in the loop’ simulation facility, which improves operational safety and vehicle availability, reduces whole life maintenance costs of wheelsets and consistently maximises braking performance in all adhesion conditions.

WSPER is used by railway organisations to evaulation the low adhesion performance of full train braking systems.

WSPER makes the equipment believe that it is fitted to the train recreating realsitic operational conditions. The rig can also measure the effectiveness of adhesion equipment, such as sanders.

Organsiation Type | Value offered by WSPER |

|---|---|

Rolling Stock Owner | Improved availability & reduction in whole life maintenance cost of wheelsets Consistently maximised braking capability in all adhesion conditions Simplification of obtaining product approval |

Train Operating Company | Improved operational safety due to a reduction in poor brake performance incidents Improved availability & reduction in whole life maintenance cost of wheelsets Consistently maximised braking capability in all adhesion conditions |

Vehicle Manufacturers | Consistently maximised braking capability in all adhesion conditions Improved availability and reduction in whole life maintenance costs of wheelsets Improved operational safety due to a reduction in poor brake performance incidents |

Brake System Manufacturer | Simplification of obtaining product approval Reduced cost and time savings compared to track testing Consistently maximised braking capability in all adhesion conditions |

Validation, Accreditation and Standards

Combined with the real track based adhesion profiles, the WSPER facility has gained recognition in the UK and overseas for its ability to accurately represent the low adhesion behaviours observed in service.

Our WSPER Testing Laboratory is accredited and regulated by the United Kingdom Accreditation Service (UKAS), in accordance with International Standard ISO/IEC 17025:2017. This provides us with a recognised industry mark of quality and demonstrates our technical competency for the defined scope specified in our schedule of accreditation, which can be viewed here

In addition to accredited testing as defined above, DB ESG can also provide testing to other national standards and bespoke testing programmes, these include:

- Testing to UK national standards – RSSB GM/GN2695, LUL S2180

- OEM product development

- R&D

- Service Problems

- Accident investigation support

- Train performance modelling

3D Printing of Components

What is 3D printing?

- 3D printing, also known as Additive Manufacturing (AM), is a process of making three dimensional solid objects from a digital file. An object is created by laying down successive layers of material until the object is formed.

- 3D printing enables the production of complex shapes using less material than traditional manufacturing methods.

- This makes it ideal for production of small volumes, where replacement components can be provided on demand and to short lead times.

What are the key benefits of 3D printing?

- On-demand, just in-time production of parts.

- Reduced cost, eliminating the need for spares holding, and costly tooling and jigs.

- Use of high-performance, cutting-edge materials, with advanced mechanical properties e.g. high strength, light weight.

- Ability to manufacture parts much quicker, in days rather than months.

- Freedom to design customised parts, unique to the customer requirements.

- Greater consistency of parts.

- Ability to keep passenger trains in service for longer with efficient replacement of components.

Why 3D printing is the future of train component manufacturing?

Manufacturing rolling stock is expensive because train fleet production runs tend to be lower volume compared to other manufacturing industries. This low volume drives up the manufacturing cost, removes the incentive to invest in research and development, and reduces the number of suppliers able to compete.

The challenge is exacerbated by the issue of obsolescence; trains can be in operation for 30 or more years. To keep these fleets operational and in peak condition, asset managers need to ensure the continued supply of parts for which the original manufacturing drawings may no longer exist, and that may only be needed in very small quantities for the remainder of the vehicle’s life.

Such legacy, high value, but low volume parts are a real struggle for the existing supply chain and manufacturing methods, leading to many operators having to expend unnecessary amounts of effort and cost concerning these parts. Legacy parts are generally expensive, have very long lead times, and are often not tailored to the specific fleet or application.

3D printing is the solution to these manufacturing challenges, allowing replacement parts to be produced at low cost, low volume and with short lead times. Train interiors can also be personalised by operators, and depots can have their own printers to enable parts to be manufactured on demand.

How reverse engineering supports the 3D printing of components?

- When an object is designed it is normal to create detailed designs that explain how the component is created. Reverse engineering is used for situations when these detailed designs are no longer available e.g. with legacy/obsolescent parts. The process starts with the item and works backwards through to the design process to obtain the original design information.

"DB ESG can support you throughout the whole process." |

|---|

What is DB ESG’s expertise in 3D printing?

DB ESG provides the engineering design, assessment and approvals for the introduction of 3D printed components on UK train fleets, ensuring that parts comply with railway standards and operating environments. We study the end-to-end process of supplying new 3D printed rail vehicle components, from initial reverse-engineering design, through to approvals and manufacture of the final items.

We were the first in the UK to fully approve 3D printed components, now running on UK passenger trains. This is the first-time production-ready 3D printed parts have been fitted on passenger trains within the UK. The trial will be extended to other operators over 2020/21.

DB ESG are involved in considerable research and development using this technology.

End of expander contentCondition Based Maintenance

Modern rolling stock is technically intelligent and all of the various sub systems can be monitored to provide intelligent data enabling predictive maintenance, leading to capacity improvements and saving energy.

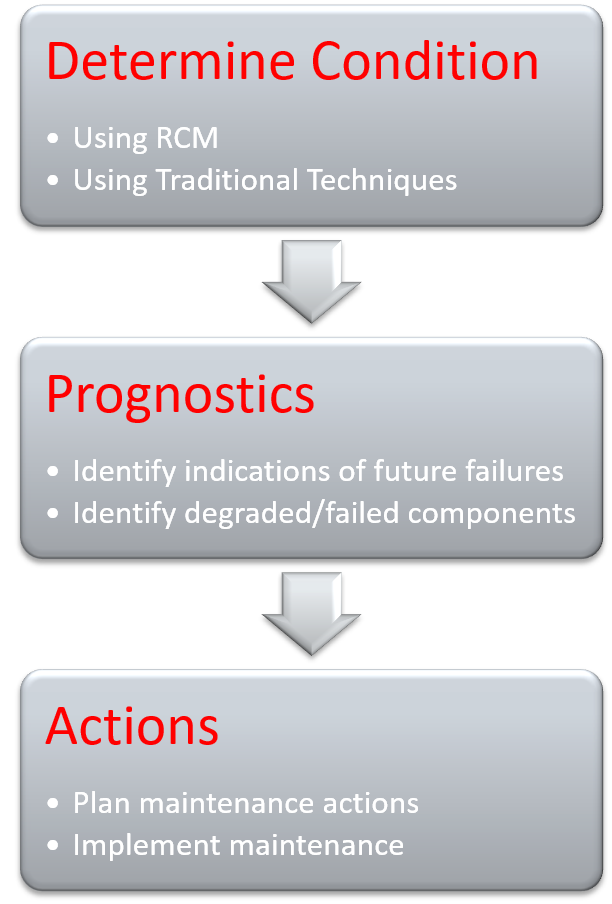

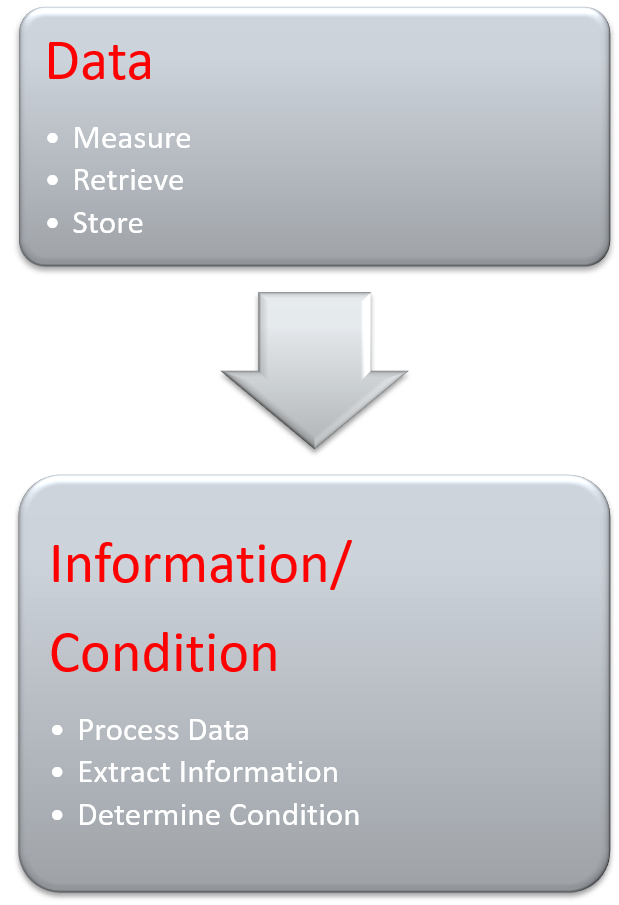

What is Condition Based Maintenance (CBM)?

The determination of required maintenance actions based on the actual condition of the component, which has been calculated by systematically collecting data from an asset over a period of time.

What is Remote Conditioning Monitoring (RCM*)?

Remote condition monitoring is the tool used to determine CBM i.e. it is the collection and analysis of data in order to work out the condition of a component.

*(RCM=Determination of the condition of a component via automatic collection and analysis of data)

How can DB ESG help?

DB ESG have a wealth of expertise to support operators in this area, having a wide range of experience in RCM and maintenance optimization. They have employees with backgrounds in depot maintenance, new build maintenance plan creation, fleet operations planning, refranchising support, RCM systems development and ‘big data’ analysis.

Bringing all this expertise together allows DB ESG to use a holistic approach to maintenance optimisation that looks at the whole system in which the fleet operates. Our expertise in the field of RCM and data analysis is supported by our wealth of experience in rolling stock engineering.

DB ESG also have UK experience in designing, approving and installing RCM systems onto trains.

End of expander contentTesting & Homologation

DB has a wealth of experience in the testing, approvals and commissioning of new train fleets for customers around the world, including the Velaro Eurostar, ICE 4, FLIRT, Vectron and Desiro. In addition, DB has also support Hitachi Rail Europe in the UK with testing and homologation of their new Intercity Express and ScotRail AT200 fleets.

We can provide the following:

- Planning and control for all required assessments and certifications, both on track and in laboratory

- Planning for the required testing scope in all applicable countries, optimisation of the test duration and coordination with the relevant authorities

- Execution of testing routines

- Coordination and organisation of documents and reports required by the bodies and authorities involved

- Proof of conformity as NoBo, DeBo and AsBo

- Verification of documentation and quality

- Drafting of documentation and assessment in test reports

- Explanation of results

- Organisation of pertinent legal approvals, including network access for test runs

- On-line running tests

- Acceptance of the trial testing vehicle

- Planning and control of all required testing activities

- Creation of assessments and expert appraisals for network access/permits from licensing authorities

- Submittal of timetables for on-line running tests

also

- Systems engineering

- Component replacement & validation

- Technology feasibility, trial and demonstration

- Hybridisation of rolling stock

- Human Factors, Ergonomics and interiors performance, including assessment

- Non-destructive testing

- Risk assessment & root cause analysis

- Structural analysis

- Vehicle performance & specification