Article: Remote Condition Monitoring & Condition Based Maintenance

What is Condition Based Maintenance (CBM)?

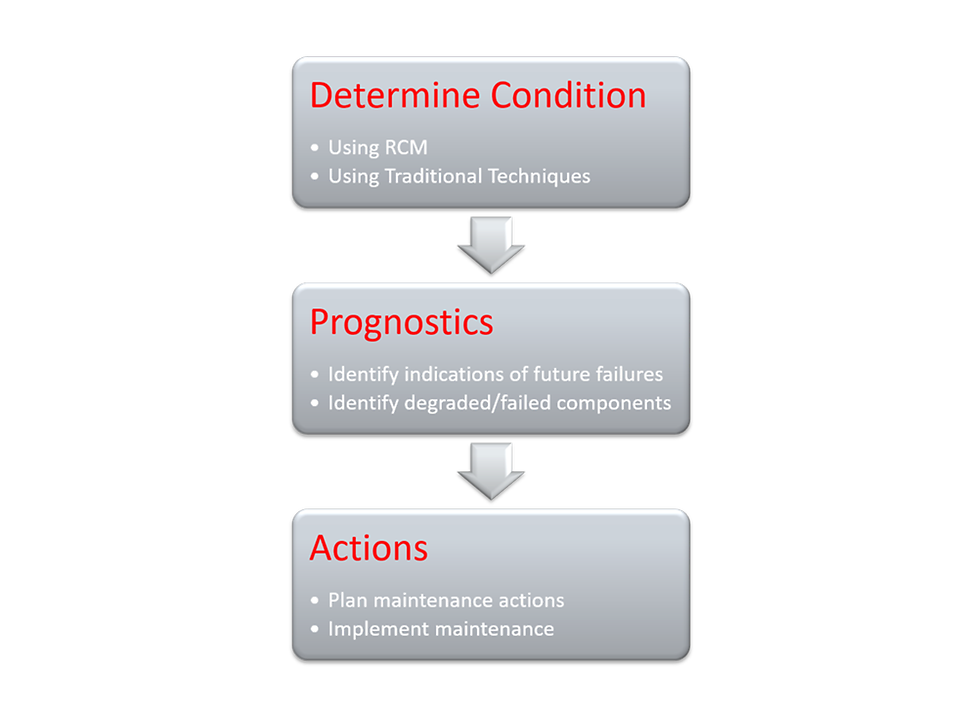

The determination of required maintenance actions based on the actual condition of the component, which has been calculated by systematically collecting data from an asset over a period of time.

What is Remote Conditioning Monitoring (RCM*)?

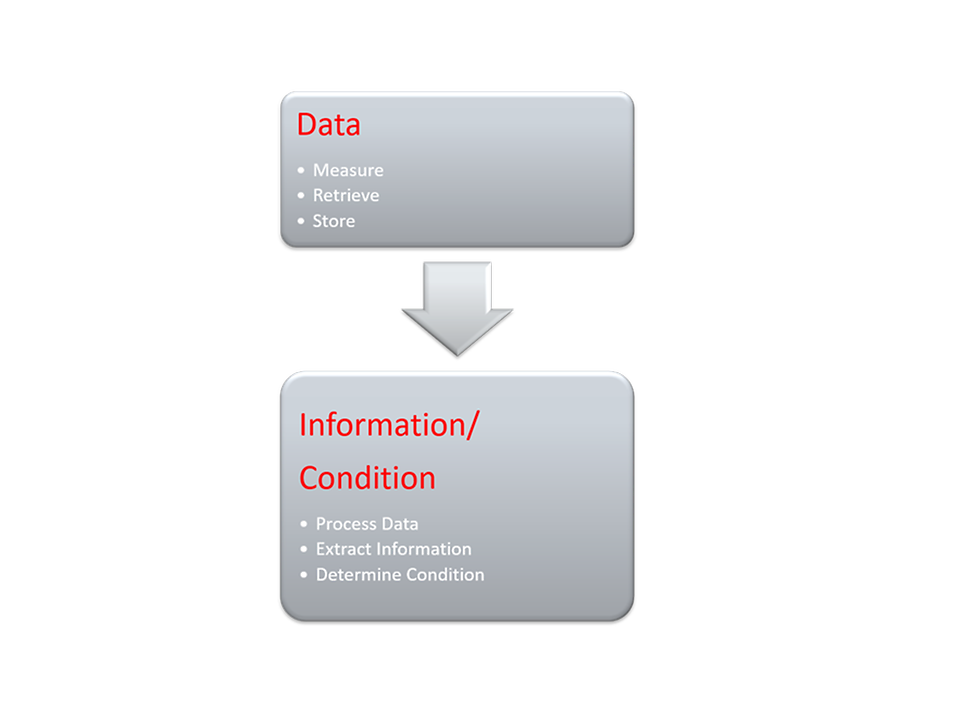

Remote condition monitoring is the tool used to determine CBM i.e. it is the collection and analysis of data in order to work out the condition of a component.

*(RCM=Determination of the condition of a component via automatic collection and analysis of data)

How can DB ESG help?

DB ESG have a wealth of expertise to support operators in this area, having a wide range of experience in RCM and maintenance optimization. They have employees with backgrounds in depot maintenance, new build maintenance plan creation, fleet operations planning, refranchising support, RCM systems development and ‘big data’ analysis.

Bringing all this expertise together allows DB ESG to use a holistic approach to maintenance optimisation that looks at the whole system in which the fleet operates. Our expertise in the field of RCM and data analysis is supported by our wealth of experience in rolling stock engineering.

DB ESG also have UK experience in designing, approving and installing RCM systems onto trains.