Article: Brake System Technology (WSPER)

Overview

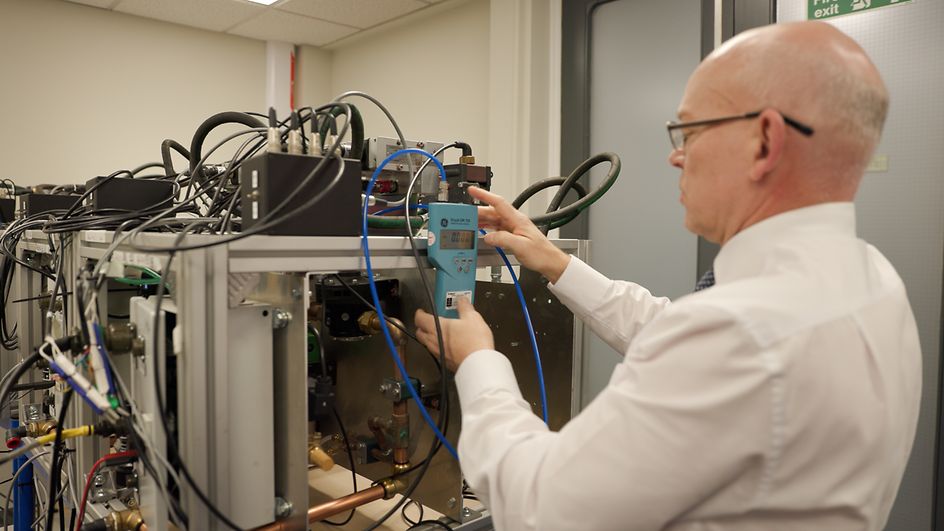

DB ESG's wheel slide protection evaluation rig (WSPER) is a real time ‘hardware in the loop’ simulation facility, which improves operational safety and vehicle availability, reduces whole life maintenance costs of wheelsets and consistently maximises braking performance in all adhesion conditions.

WSPER is used by railway organisations to evaulation the low adhesion performance of full train braking systems.

WSPER makes the equipment believe that it is fitted to the train recreating realsitic operational conditions. The rig can also measure the effectiveness of adhesion equipment, such as sanders.

Organsiation Type | Value offered by WSPER |

|---|---|

Rolling Stock Owner | Improved availability & reduction in whole life maintenance cost of wheelsets Consistently maximised braking capability in all adhesion conditions Simplification of obtaining product approval |

Train Operating Company | Improved operational safety due to a reduction in poor brake performance incidents Improved availability & reduction in whole life maintenance cost of wheelsets Consistently maximised braking capability in all adhesion conditions |

Vehicle Manufacturers | Consistently maximised braking capability in all adhesion conditions Improved availability and reduction in whole life maintenance costs of wheelsets Improved operational safety due to a reduction in poor brake performance incidents |

Brake System Manufacturer | Simplification of obtaining product approval Reduced cost and time savings compared to track testing Consistently maximised braking capability in all adhesion conditions |

Validation, Accreditation and Standards

Combined with the real track based adhesion profiles, the WSPER facility has gained recognition in the UK and overseas for its ability to accurately represent the low adhesion behaviours observed in service.

Our WSPER Testing Laboratory is accredited and regulated by the United Kingdom Accreditation Service (UKAS), in accordance with International Standard ISO/IEC 17025:2017. This provides us with a recognised industry mark of quality and demonstrates our technical competency for the defined scope specified in our schedule of accreditation, which can be viewed here

In addition to accredited testing as defined above, DB ESG can also provide testing to other national standards and bespoke testing programmes, these include:

- Testing to UK national standards – RSSB GM/GN2695, LUL S2180

- OEM product development

- R&D

- Service Problems

- Accident investigation support

- Train performance modelling