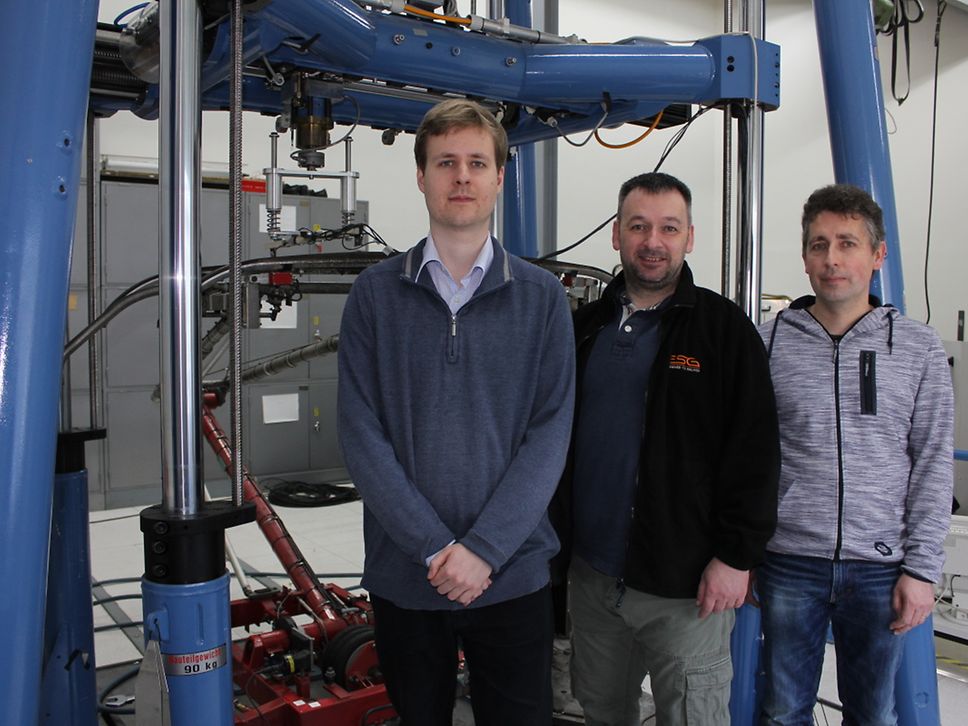

Article: ESG´s pantograph testing team

ESG Rail’s pantograph testing team are helping to deliver a competent and responsive service to Hitachi Rail Europe:

Interview with the team. DB Systemtechnik (DBST) has a contract with Hitachi Rail Europe, to run the testing and commissioning programme for the new fleet of Intercity Express Trains. DBST has a wealth of experience in the testing, approvals and commissioning of new trains across Europe, but this was their first project of this type in the UK, although they have since received an additional UK order from Hitachi.

ESG Rail has stepped up to support DBST with this project and are working on behalf of DBST as part of the pantograph testing laboratory. Having worked alongside DBST engineers since March 2017, the ESG team is now entrusted with carrying out this testing without DBST support, negating the need for German engineers to travel to the UK.This project has been a new learning experience for the UK based ESG team.

The team includes Ajtony Farkas, who is known as the ‘Pantograph Guru’ by the other team members. Ajtony is a Graduate Mechanical Engineer and has very quickly grasped this new technology and become somewhat of an expert. They have formed some very close working relationships with Hitachi, Network Rail and DBST, and are enjoying the project’s many challenges. The team were asked to share some of their experiences on this project to date.

What have you enjoyed most about this project so far?

David Weston: “It has been great to work with Hitachi, the Hitachi team are friendly, professional and organised.”Ajtony Farkas: “It is easy to mistake these tests as a simple ‘no-brainer’ task of pressing buttons in a predefined order, but yet every time we are presented with different challenges we’ve never seen before, whether in the data or on the roof of the train. Making those things right is what this is all about, and as an engineer it feels fulfilling to solve and manage any unexpected project challenges, and to make the customer happy and confident in our abilities and expertise.”Stewart McDonald: “We have built up a great rapport with our customer. We are on first name terms with the Hitachi team.”David Weston: “Very interesting to learn new skills as well.”

What challenges have you faced?

Ajtony Farkas: “During the first weeks of testing, when we shadowed the German colleagues and put our notes from Munich to practical use, the language barrier often made it difficult for us to fully understand why they do things the way they do. However, once we broke the ice, learning new practices from the Test Engineers coming over from Germany was extremely beneficial.Due to the nature of testing, we are dealing with many unknowns. This means we can never be 100% sure about the plan, and this manifests in short notice changes, dealing with phone calls late at night and early starts. It is never the same!Testing is also very demanding in terms of trying to get many things done in a tiny window of opportunity. For example, we have to process the recorded data, while discussing the next step with the signallers, Freightliner, Network Rail, and Hitachi, and at the same time, conveying information to the German colleagues 200m away in the other IEP unit. All this whilst answering questions from visitors working at Academia, TOCs, and ROSCOs can be overwhelming at first. However after a while we developed a focus for the job that needs to be done first, and all of this got quite enjoyable.”Stewart McDonald: “The early mornings have been a challenge, out before 6am, however the fresh air soon takes me from my slumber to a more alert state in the blink of an eye. The frantic pace at the depot can also be challenging, getting equipment calibrated and ready for the testing. We are all soon in our element, pushing buttons and producing graphs that would baffle most onlookers.”David Weston: “The German language barrier required my very best translating skills at times, I am now considering learning German to improve this communication.”

How do you hope to further develop your new skills?

David Weston: “I am looking forward to gaining a better understanding of the forces and technical aspects of the pantograph testing and being able to fully understand the more technical aspects of pantograph testing and data analysis.”Ajtony Farkas: “I wish to extend the UK team’s capabilities by helping out DBST in different areas of pantograph testing. We are not just collecting data anymore, but we are now able to evaluate pantograph behaviour and recommend improvements to the current collector systems we are testing. The next step is to undertake pantograph instrumentation and continuously improve the testing equipment and software. The team also has to gain more exposure by doing different tests (not necessarily in the UK) which I hope we will get a chance to do in the near future.”Stewart McDonald: “The pantograph testing has given me exposure to another new fleet and the intricacies associated with the test regime. This will no doubt benefit, not just myself, but also DB for future bids on new rolling stock to undertake the same testing.”

What new skills have you learned?

Stewart McDonald: Having spent time in Germany on the Pantograph Test Rig and having undertaken dynamic testing on both the East Coast Mainline and the Great Western Mainline, I have increased my knowledge of pantographs and how they interact with the infrastructure tenfold.”Ajtony Farkas: “Recently I had the chance to manage and develop the team by preparing David for the ups and downs (no pun intended) of pantograph testing, showing him the basics of conducting tests in both units, the quirks of post-processing the deliverables for Hitachi, and managing his entry to the test team. He picked up a great deal of knowledge very quickly and was able to conduct tests under supervision after only three days.”David Weston: “Despite being thrown in at the deep end, I have managed to learn how to test the pantographs, assimilate the data and prepare the test reports required for Ajtony to compile into a formal test report for Hitachi.”

How has the project been different from other projects that you have worked on in the UK?

Ajtony Farkas: “It is more difficult to define the scope for testing, as it needs to incorporate a greater amount of flexibility than other projects I have worked on. Testing contains a myriad of variables we cannot control, therefore more contingency days are required than usual. Depending on the outcome of each contact force measurement run, the original plan had to be revised quickly, adding more test days if needed.”David Weston: “Working in the field and with the customer is both rewarding and challenging in that you are expected to deliver an end result there and then. Generally I am in an office designing new circuit modifications or writing reports.It makes a welcome change to work in the field, especially for and alongside, such professional companies as DB and Hitachi.”Stewart McDonald: “I have never been directly involved with commissioning or testing within my rail career to date and this opportunity has given me a valuable insight into the relationship between all three parties.”

How can we help?DB - ESG is the route to market for the DB Systemtechnik and DB Engineering and Consulting product and service portfolios in the UK. We can rapidly deploy existing and proven solutions on to the UK rail network, enabling values to be realised earlier in the project lifecycle.

Talk to the expertsTo understand more, contact us directly via db-esgrail@deutschebahn.com