Article: 3D Scanning Services and Solutions

DB ESG Expertise

DB ESG offers a 3D scanning service to the UK rail sector. 3D scans of rolling stock components, space envelopes, or entire rolling stock units can be taken for the purposes of: -

- Replacing obsolete parts, converting scans into CAD files and re-designing for digital manufacturing.

- Re-engineering components with design flaws and making design improvements for Digital Manufacturing (DM).

- Inspecting components for issues, wear, and conformity.

- Aiding the design and installation of new technologies, by scanning space envelopes to help determine clearance requirements and fixing points.

- Providing a greater understanding of rolling stock units, classes and variations.

Examples of Work Undertaken by DB ESG

1. Cab desk variations - driver training and maintenance instructions.

DB ESG 3D scanned each cab desk variant in the Class 170 fleet operated by East Midlands Railways (EMR). With five different Class 170 variants, EMR wanted to better understand the differences, to help them with the vehicle maintenance, driver instructions and training. The differences between the variants were clearly identified in a graphical report.

2.Component inspections –

2.1 Bulkhead repair feasibility.

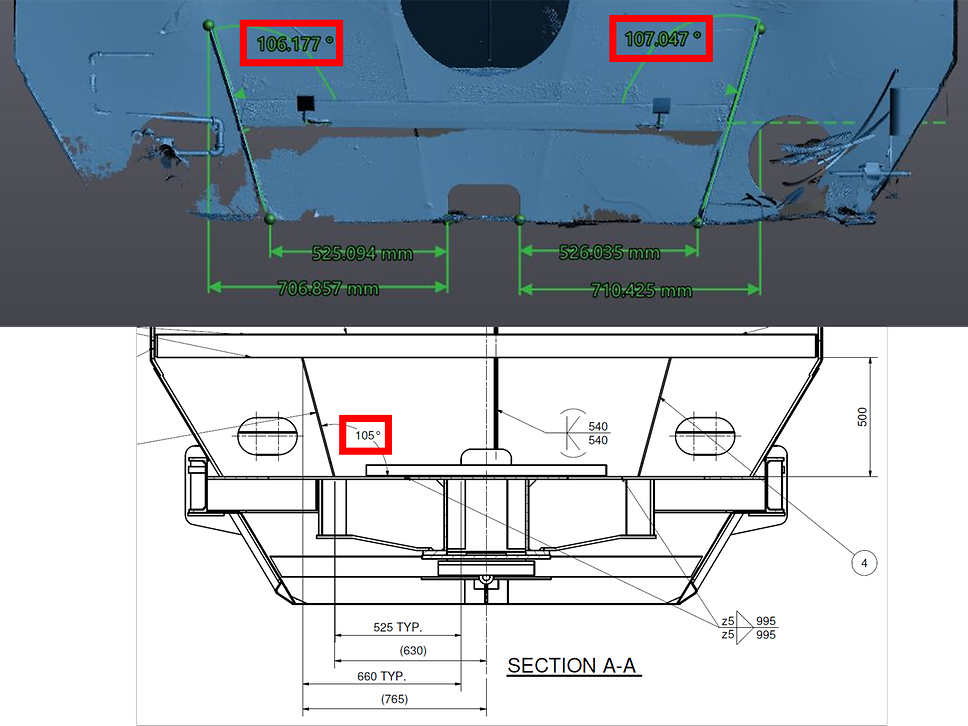

Cracks were detected on sloped bulkhead plates on HTA wagons during a maintenance inspection. A repair procedure had already been developed for a different fleet of the same type. DB ESG 3D scanned the bulkhead and surrounding area on HTA wagons for Wabtec UK, to determine if these wagons were sufficiently similar so that the existing repair procedure could be utilised.

2.2 Structural review of fuel tanks.

Two Class 158 fuel tanks operated by EMR had failed. DB ESG were asked to use 3D scanning to investigate the state of all the tanks, determining whether they require action before the planned 2024 overhaul. DB ESG 3D scanned one of the failed tanks to obtain an accurate 3D model to highlight the issue, comparing this to a CAD model created from the original fuel tank drawings. DB ESG then visited a depot to inspect and 3D scan fuel tanks in situ on the Class 158 vehicles. All the CAD models created, were analysed using FEA and a structural report was provided, which supported EMR’s investigation to resolve the issue.

3. Design and installation of new technologies – Class 92 battery charger and energy metering.

DB ESG recently scanned the entire roof area and a cabinet in a Class 92 locomotive to help determine the space available for a new battery charger and energy metering system. This work is being carried out for DB Cargo, as part of a traction and battery upgrade project for the Class 92 electric locomotives.

4. Re-engineering of components for potential production via DM.

DB ESG utilises 3D scanning to re-engineer parts that have no or very limited existing drawings or information. This process captures real-world data to make design improvements to remove issues, or improve efficiency in the engineering process.

DB ESG typically produce these parts using Digital Manufacturing (this includes 3D printing, CNC machining, and injection moulding) to allow low and high volume production runs in various different materials, form fire compliant polymers, to aluminium and steel, as well as flexible parts.

Talk to the Experts

To arrange for DB ESG to visit your facility to 3D scan any problem or obsolete parts, or to discuss any other potential 3D scanning applications, email: -daniel.hartley@dbesg.com