Article: Re-design and Additive Manufacturing of Sensor Housing

Overview

DB ESG’s Digital Manufacturing expertise, including 3D printing (also known as additive manufacturing or AM) is not only a great way of sourcing obsolete components, but it can be used to solve component design flaws, with the added advantage of being able to produce prototypes to trial design reiterations.

Background

In 2022, Angel Trains asked DB ESG to re-design and additively manufacture a sensor housing for an environment monitoring sensor, which was to be fitted to the interior of rolling stock. This sensor is used to measure temperature and humidity levels within the passenger areas.

The sensor housing design needed to not impact on the functionality of the environment monitoring sensor and ensure that the components would not be damaged in service, whilst meeting fire compliance requirements as per BS EN 45545-2:2020.

The design of the original sensor housing had several design flaws, including:

- No closing mechanism to join the two halves of the unit together (the original design, therefore, had to be held together with painter’s tape).

- No method of securing the battery inside the unit to hold it in place.

- No fire compliance and a poor surface finish. New design to be printed using FDM (Fused Deposition Modelling) technology with Ultem™ 9085 Black material to ensure fire compliance to BS EN 45545-2:2020.

Work Undertaken by DB ESG

In 2022, DB ESG redesigned the sensor housing to incorporate the requested design changes.

- A CAD model was produced that incorporated the improved design solutions, which included:

- Snap fit joints designed into both halves of the sensor housing to allow them to securely connect to each other and be easily taken apart for sensor access.

- Semi-circular battery mounting feature to hold the battery securely in place.

- Mounting feature for circuit board installation using self-tapping screws.

- The design was also refined for production using FDM (Fused Deposition Modelling) AM technology with Ultem™ 9085 Black material, to meet fire compliance requirements.

- Production of a 2D drawing of the sensor housing to support the 3D models that are used for manufacture.

Five sensor housings were 3D printed and sent to Angel Trains.

In 2023, Angel Trains requested a variation to the design, to include:

- The mounting of 3 batteries (instead of the 1 battery originally specified) and a longer circuit board (as the environment sensor is now integrated into the new circuit board instead being a wired antenna connection as originally designed).

- In addition to the snap fit design to close the sensor housing halves together, two heat inserts have also been designed into the sensor housing so that Torx safety screws can be used as secondary retention.

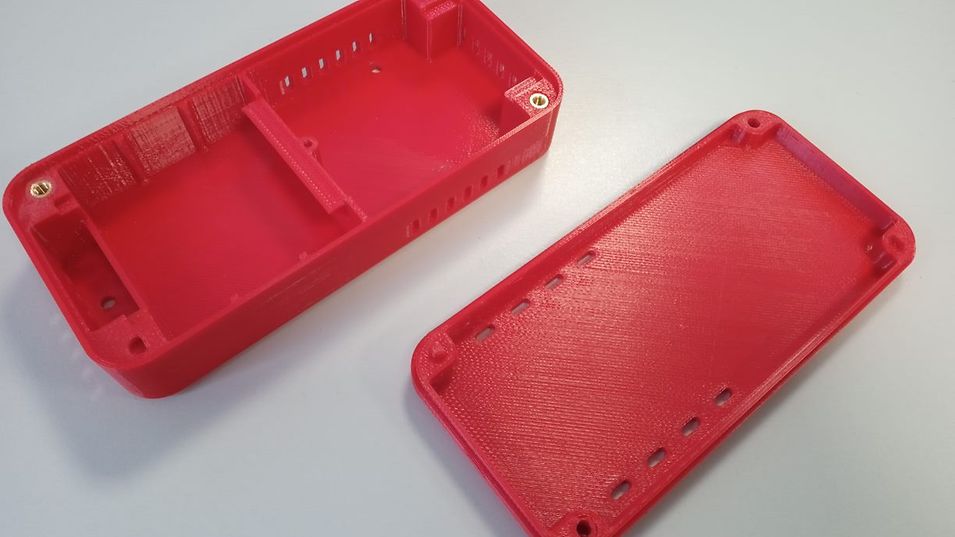

- Production of a 3D printed prototype using FDM technology and PETG material for trial purposes.

- An investigation into the optimal fire compliant materials available for FDM AM production (Markforged Onyx FR vs Ultem™ 9085 Black).

In addition to these changes, the variant sensor housings were required to maintain all the features previously re-designed.

- Angel Trains were provided with a PETG prototype of the sensor housing variant for approval and trial (see images below). Based on the information provided to Angel Trains regarding the potential fire compliance materials (Markforged Onyx FR or Ultem™ 9085 Black) Angel Trains are to provide DB ESG with their preferred choice which will then be used to additively manufacture a further 5 sensor housings.