Article: Overview of Our Digital Engineering Service

DB ESG is at the forefront of rail innovation, using its cutting-edge Digital Engineering (DE) Service to revolutionise component production. Using advanced computer-aided processes such as 3D scanning and additive manufacturing (3D printing), DB ESG delivers rapid, cost-effective solutions to the rail industry.

Our mission is to leverage this advanced expertise to tackle some of the most pressing challenges in rail—addressing obsolescence, minimising vehicle downtime, optimising maintenance procedures and providing condition-based monitoring to ensure vehicles stay on track and operational longer.

By combining digital technology with world-class engineering, we’re transforming the way rail vehicle parts are designed and produced.

Our Digital Engineering service ensures that the future of rail transport is not only more efficient but more resilient, sustainable, and innovative.

Our Pedigree

DB ESG has extensive experience in digital manufacturing for the UK rail sector, having started our journey with 3D printing and 3D scanning technology in 2018. Working with asset management company Angel Trains, we were the first in the UK to place 3D-printed parts into commercial service on passenger trains in 2019. Since then, we have expanded our service rapidly, supplying DE components and services to OEMs, TOCs, and ROSCOs. We have successfully completed over 100 projects for more than 20 customers, addressing component supply challenges and solving engineering problems efficiently.

Our project portfolio is diverse, ranging from small, flexible clips designed to replace brittle originals that failed during overhaul—delivered within six working days to minimise service disruption—to large, impact-resistant underframe protection panels that safeguard vital systems and circuitry.

DB ESG’s DE service operates across three key workstreams:

- Obsolescence Management

- Vehicle Performance

- 3D Scanning

Initially focused on mitigating component obsolescence, DB ESG now produces parts from a wide range of materials, including metals, without minimum order constraints. This enables rapid part production, often within days, helping keep fleets operational and maintenance schedules on track. Unlike traditional manufacturing, DE incurs no setup or tooling costs, offering a bespoke, flexible, on-demand service.

We always select the manufacturing method that is most suited to the specific requirements of the end user.

Whilst 3D printing is one of our core strengths, we still utilise other, readily available production methods in our Digital Engineering Service offering, such as CNC machining, Laser profiling, Casting and Glass Reinforced Plastic (GRP) moulding. Not every part is suitable for 3D printing. This might be due to insufficient complexity, cost or speed. It might also be that a requirement demands a specific material is used or a particular standard is met and utilising a more established production method is more appropriate.

Digital Engineering - Bespoke, On-Demand Production

We are focused entirely upon problem solving. Whether the problem is obsolescence, long lead times, large minimum order quantities or price-rises. Our solutions are not just merely centered around replacing parts and components, we can create bespoke items entirely from scratch. We have used 3D printing across a wide range of use cases from small interior panel clips to large, structurally vital components. Phones, armrests, paneling, cab-desks and impact-resistant exterior parts such as brake-box covers. DE allows for ultimate flexibility. This ultimate flexibility allows us to address the specific reason for your enquiry resulting in targeted problem solving.

We also use AM to produce rapid prototypes that can be sent to the end customer prior to production ordering. These prototypes can be produced by one of our suppliers or in-house using one of our 3D printers. These prototypes allow for interactive design changes to be carried out to meet the specific application requirements, ensuring that you’ve ordered a part that you can rely on. It also means that we eliminate the risk of future supply; ensuring the component is not only right but optimised.

End of expander contentWhat is Digital Manufacturing?

Digital Manufacturing (DM) is the design, development and production of physical parts using computer aided processes such as CAD, 3D printing, and programmable CNC machines. Thus, eliminating the need for 2D drawings, reducing production time, and ensuring repeatability of production.

DM allows complete freedom of production; re-engineering parts that you are struggling to source, adding design improvements or creating new components from scratch. All at a cost competitive and even cheaper than traditional methods, with no minimum order quantity.

End of expander contentWhat is Additive Manufacturing?

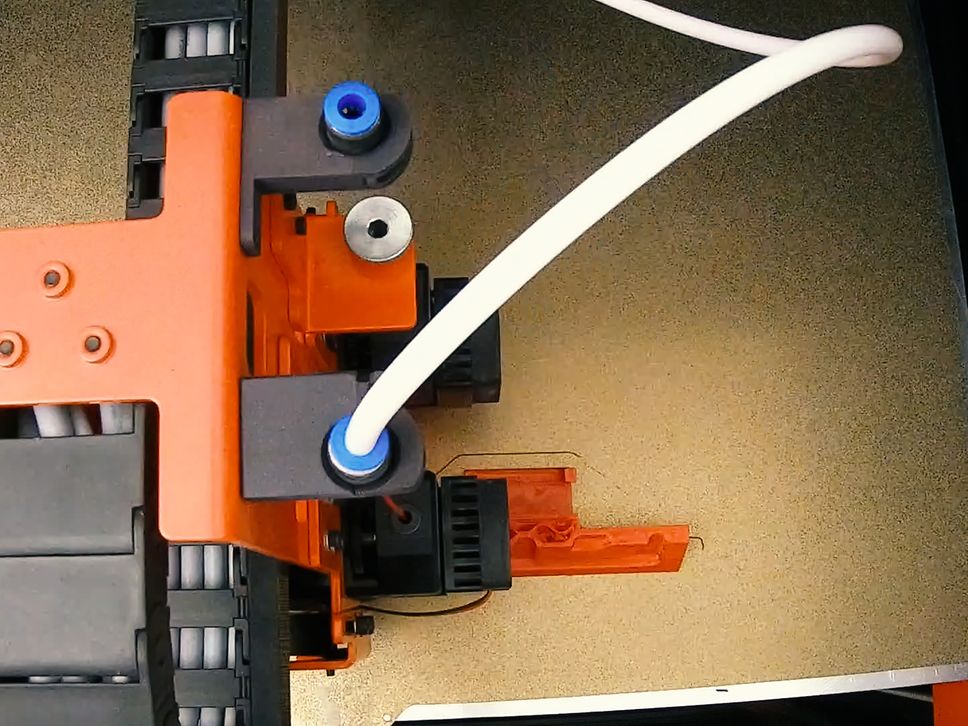

Additive Manufacturing (AM), is the industrial production name for 3D printing; the term describes any process in which material is deposited, joined or solidified layer by layer to form a 3D part or component,

There are many different processes and materials used within AM. The most common process is Fused Deposition Modelling (FDM) where filament is melted and deposited layer by layer onto a print bed. We also have experience in many different processes such as Selective Laser Sintering (SLS) where powder material is bonded together using lasers, Multi Jet Fusion (MLF) where powder material is bonded together using inkjet arrays and Stereolithography (SLA) where resin material is cured using UV light. All of these processes are used to manufacture polymer parts and components, but we also have experience with many different material methods, including metal AM processes, such as Selective Laser Melting (SLM) where powder metal is bonded using lasers.

We are also heavily invested in emerging 3D printing technologies such as Wire Arc Additive Manufacturing (WAAM) and Directed Energy Deposition (DED), which allows us to 3D print larger metal parts and components.

Our R&D workstream is researching yet more materials, such as carbon/glass fibre reinforced filaments and even more fire compliant materials to railway standard BS EN 45545.

Key Benefits of Additive Manufacturing

- On-demand production of replacement parts/components, solving obsolescence and supply chain issues.

- Shorter lead times and small order quantities eliminate the need for long-term, large-scale spares holding, reducing whole life rolling stock costs.

- The use of high-performance materials, with advanced mechanical properties, to meet all relevant railway industry standards.

- Unlimited complexity in part/component design, freedom to customise parts and design for unique customer and application requirements.

- Reductions in spare part/component costs.

- Reductions in vehicle maintenance downtime due to fast on-demand production and supply of replacement parts.

- Ability to keep passenger trains in-service for longer with improved designs that exhibit reduced failure rates leading to greater vehicle efficiency.

- Ability to produce prototypes quickly to test fit, form and function whilst iteratively designing out issues before proceeding with production batches.