Article: Turbostar Fuel Tank Inspections for Porterbrook Leasing Ltd.

Overview

In November 2022 there was a catastrophic failure of a fuel tank during refuelling. A second tank failed structurally in 2023. Although these failures were from a different vehicle class, in response, Porterbrook commissioned DB ESG to inspect a sample of the fuel tanks in their Turbostar fleets to assess structural integrity and identify any potential risks.

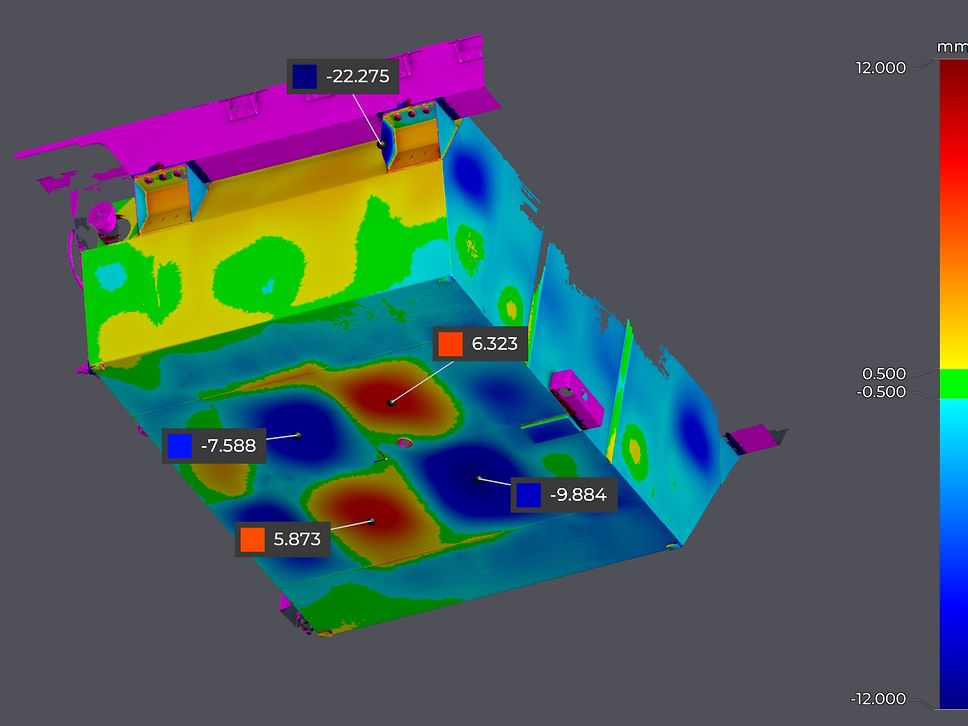

Using advanced 3D scanning and ultrasonic thickness testing, DB ESG inspected 5% of the Turbostar fuel tanks during 2023. Further inspections were performed in 2024. These assessments have proved invaluable, leading Porterbrook to integrate fuel tank scanning and through-paint wall thickness measurements into their C4 overhaul programme for the Turbostar units.

Work undertaken by DB ESG

- Jigs were designed and 3D printed to support the inspection and align with key measurement points. Additional jigs were designed and manufactured in response to emerging data on corrosion, microbial contamination and fuel blooms.

- Method statements and risk assessments were produced to ensure safe and consistent inspections.

- On site inspections of required units at Central Rivers, Aylesbury and Haymarket depots, including: -

- Ultrasonic measurements and visual inspections.

- 3D Scanning of fuel tanks.

- Comprehensive reporting delivered to Porterbrook, including post processing scans, thickness measurements and visual findings.